Life at Beehive: Building the Future with Grit & Agility

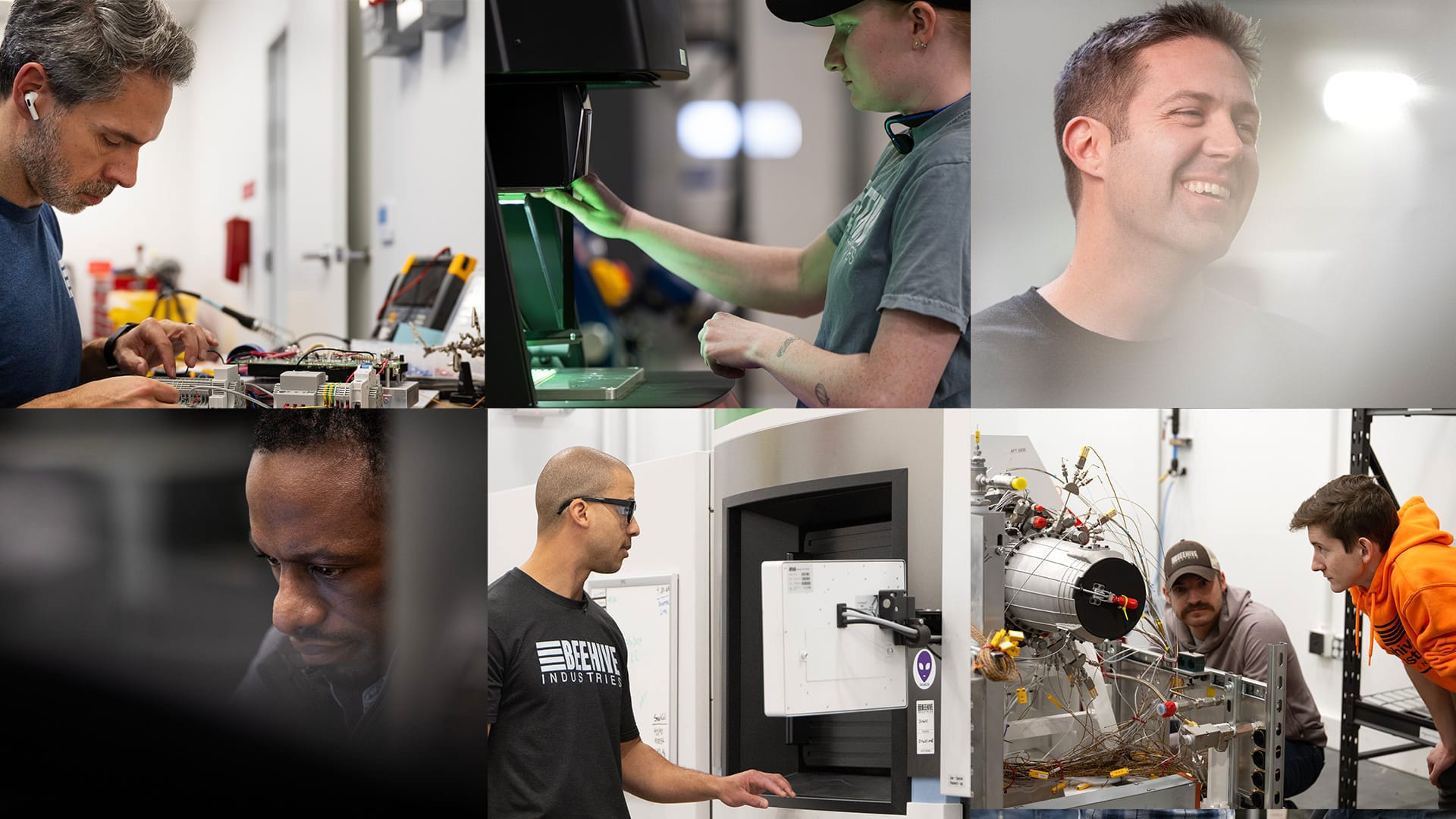

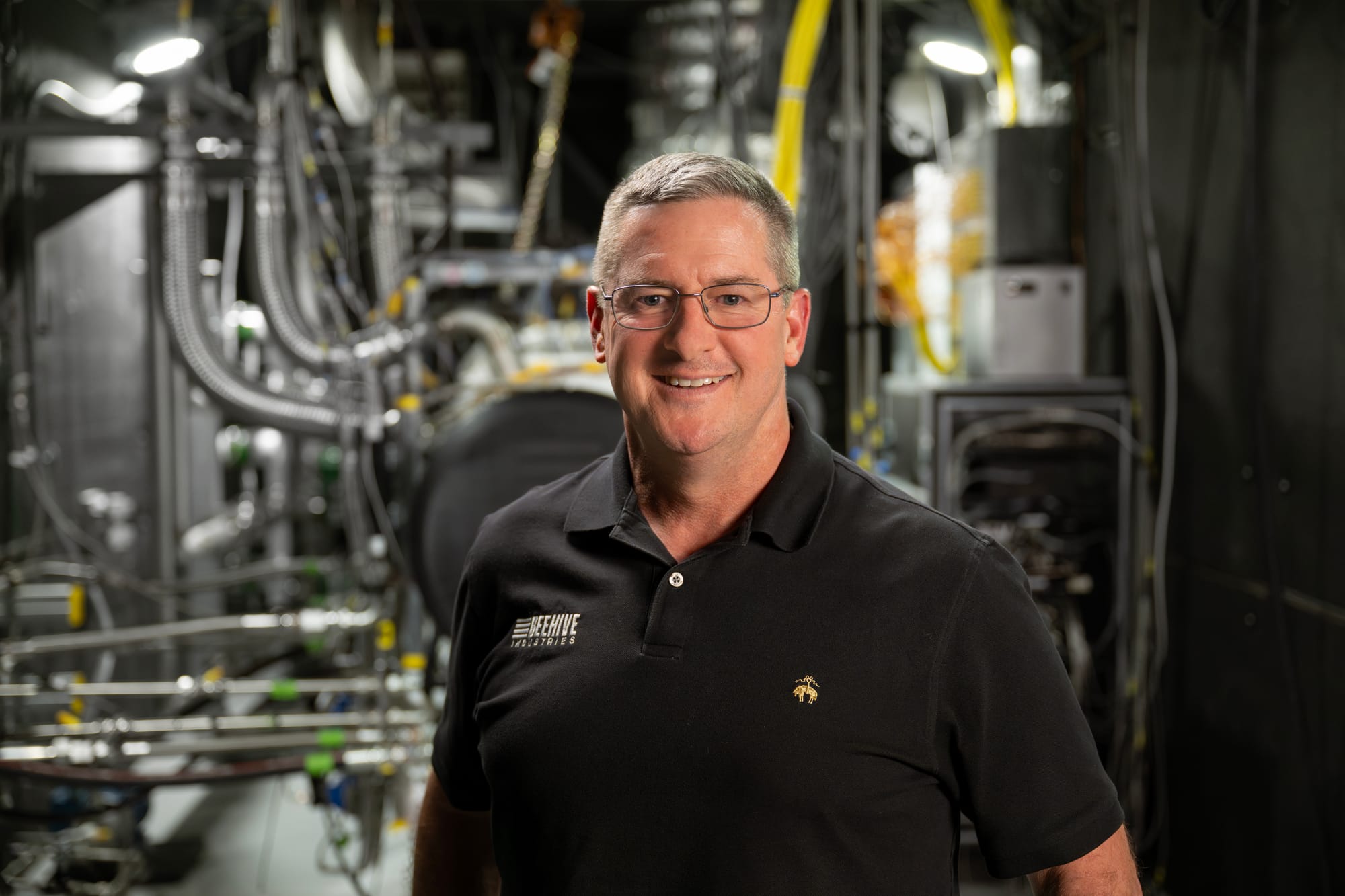

Hear from Beehive’s Chief Product Officer Gordie Follin and Lead Test Engineer Jason Chapman as they share what it takes to be a part of our powerhouse team where American-made innovation is put to work.

Are you okay working in an environment where nothing is predetermined?

The kind of place where you jump out of the airplane and build the parachute on the way down.

No limits—just solutions.

Gordie Follin, Beehive’s Chief Product Officer, knows this isn’t your average workplace. “It’s a high-octane, innovation-fueled machine that thrives on top-shelf talent, grit, and enduring perseverance,” Follin says. “We’re a high-performing team that is focused on constantly moving forward and breaking through barriers.”

We get it done, and we do it together.

Here’s what you need to know to be a part of the Beehive team:

We’re growing—fast.

We’re on track to double our workforce and we are just getting started. Our approach to jet propulsion is attracting top engineers, designers, and disruptors who drive expansion with top-tier solutions. Through advanced additive manufacturing, we’re cutting development time and costs nearly in half, setting new industry standards that shape the future of propulsion.

“What I love about working at Beehive is that every day I come in, I know exactly what I need to get done. When I leave, I can see my thumbprint on the trajectory of the company,” says Follin.

At Beehive, growth isn’t just about numbers—it’s about impact. We’re building something big, and every contribution matters.

Curiosity drives us.

Walk through Beehive headquarters and you’ll see teams locked in to tackle tough challenges head-on, their whiteboards filled with the next big breakthroughs. Curiosity isn’t just encouraged here—it’s what drives us forward.

Our strength comes from diversity, making us open-minded, agile, and able to evolve. “As a natural part of my role, I get stumped quite often. I solve those problems with other people who have different backgrounds, and we approach it from multiple angles,” says Jason Chapman, lead test engineer at Beehive. “We don’t just ask questions—we find the answers that redefine the future of jet propulsion.”

We serve those who serve.

We work hard because our frontline warfighters work harder. America is the birthplace of innovation—reshaping aviation, advancing spaceflight, and now, making a revolutionary leap in jet propulsion and additive manufacturing.

"My experience in the Navy is what brought me to Beehive," says Chapman, a Navy veteran. "I take pride in building products that serve the military."

To us, it’s not just about engineering—it’s about empowering America’s air defense with unmatched speed, agility, and performance. This is our moon landing moment, and our pursuit of excellence and love of country take the front seat as we push the limits.

We think and build differently

"Additive manufacturing allows us to react to change much faster than conventional technology,” Follin says. Whether it’s rapidly iterating on designs or optimizing performance in real time, we do it with precision and efficiency.

“There’s fantastic energy here. Everyone recognizes that we’re on the verge of something great, something that truly matters for the country,” says Follin.

The key to success? According to Follin, “Beehive’s secret sauce is a combination of talent and culture. Take away the traditional constraints of conventional manufacturing, support them with all the resources they need to get the job done, and the result is something completely different and completely special.”

We don’t wait for what’s next—we make it happen.

“We have engines for unmanned applications such as swarm drones, cruise missiles, and collaborative combat aircraft,” says Follin. “But the true value is the speed of production, built directly into the business model.”

Follin, with 25 years of experience in the industry explains, “In the broader industry, the pace of innovation is slower than it could be because the traditional propulsion OEMs are focused on manned applications. They have to follow a certain process that is constrained by the rules of passenger travel.” At Beehive, there aren’t the same roadblocks. “By focusing on unmanned applications, we can reinvent the way we design and validate things which allows us to move a whole lot faster.”

Describing Beehive’s unique approach, he adds, “We’re the only company using additive manufacturing on this scale. And when you get that right, the result is 25-35% better performance, 50-60% lower cost, and 10-15 times the production capability of current US capacity.”

Best-in-class performance, at best-in-class cost, at over 10X scale.

And to get it done, the team lives and breathes by this mantra: “Bring the best, leave the rest.”

“We have a very fast approval process,” adds Chapman. “We’re able to release parts in minutes, as opposed to days and weeks.” Taking a design from an idea to a fully tested product in a year—most manufacturers take 10 to 15 years—is what makes Beehive different.

Join us as we push the limits of what’s possible and drive America forward.

At Beehive, we don’t just build engines—we build the future.

This is where bold ideas meet real execution, where talent and tenacity fuel every breakthrough. We’re not here to follow.