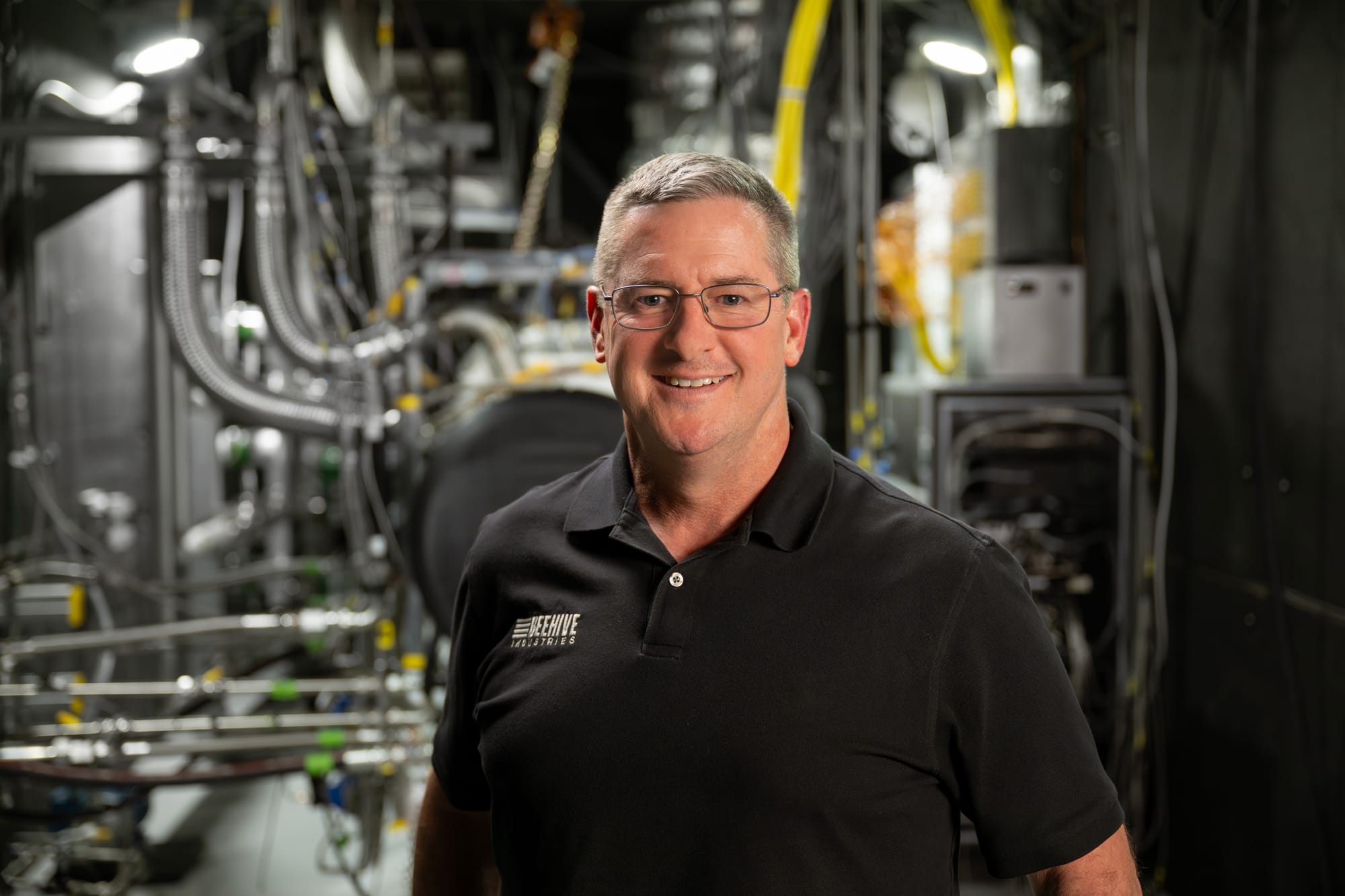

Buck Convention & Build Engines: Q&A with Beehive's Chief Product Officer

Beehive’s Chief Product Officer Gordie Follin shares the inside story on the company’s mission, innovative methods, and what’s next for American defense.

For nearly three decades, Gordie Follin has been at the forefront of propulsion innovation. With 27 years at industry giants like GE and Pratt & Whitney, he has led the development of eight engine programs across commercial aviation, military applications, and power generation—including one featuring the most additive content of any commercial aviation engine. Now, as Beehive’s head of product and commercial strategy, he’s bringing that experience to the cutting edge of defense manufacturing.

Q: What is your background?

Gordie Follin: I’ve worked for several large propulsion manufacturers over my career, developing jet engines and learning a lot along the way. While the projects were grand in scale, I often felt the pace of innovation was too slow. Many traditional propulsion companies focus on manned applications—like passenger aircraft—which are bound by strict regulations. At Beehive, we’re focused entirely on unmanned applications, which allows us to reimagine propulsion design, move faster, and truly innovate.

Q: What does Beehive do?

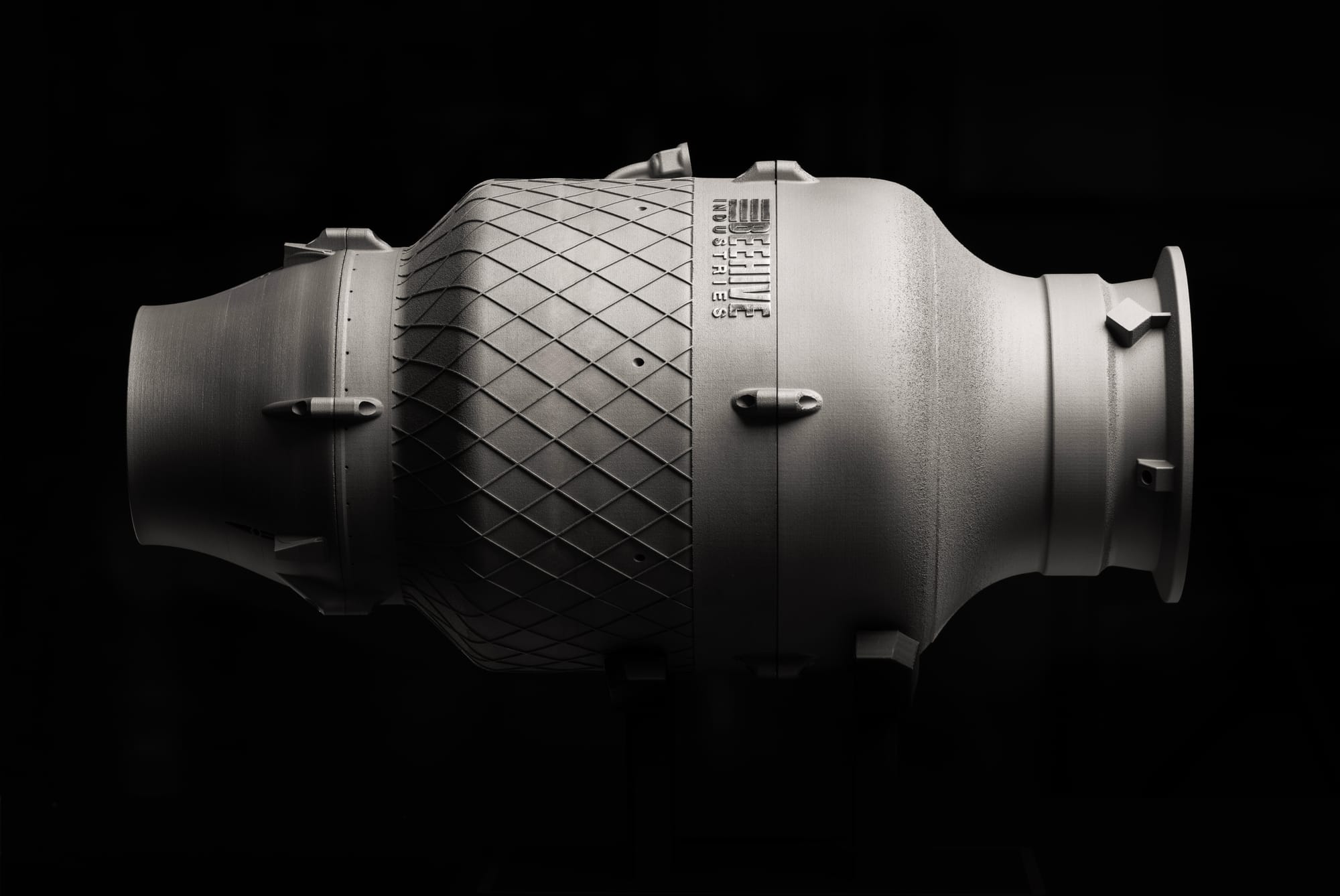

Gordie Follin: At Beehive, we’re Powering American Defense™ through the development of jet engines for unmanned aerial applications. We’re uniquely positioned to solve critical defense challenges because we have a unique combination of expertise in jet engine development, additive manufacturing, and a laser focus on these specific applications.

Q: Why does that matter?

Gordie Follin: There’s a significant gap in today’s defense capabilities. Traditional suppliers rely on outdated manufacturing processes that create bottlenecks. The Department of Defense needs 15,000 to 20,000 of these unmanned aerial systems annually, but the current production capacity is around a thousand units a year. By leveraging additive manufacturing, we eliminate reliance on those bottlenecks and can scale production to meet demand quickly and affordably.

Q: What products are currently in development?

Gordie Follin: Right now, we’re focusing on three key products. First, we’re developing engines for swarming munitions, which are small cruise missiles designed to be deployed in large quantities—hundreds or thousands at a time—to overwhelm enemy defenses. Second, we’re working on engines for longer-range cruise missiles, which are precision strike weapons requiring high performance and exceptional reliability. We’re also developing engines for Collaborative Combat Aircraft (CCA), which are unmanned vehicles that fly in formation with piloted fighter jets to perform complex, coordinated missions without putting human pilots at risk.

Q: What is an unmanned application?

Gordie Follin: An unmanned application means there’s no person on board. These applications include drones, autonomous vehicles, and munitions. Systems like these allow us to take on missions without risking human lives.

Q: What makes Beehive’s approach unique?

Gordie Follin: Our approach is unique because we design with additive manufacturing in mind—from the start. This boosts performance by 25-35%, cuts costs by 50-60%, and lets us develop engines in about a year—compared to the 3-5 years of traditional systems. Most importantly, it allows us to scale quickly, meeting the Department of Defense’s need for 10,000 to 20,000 units annually, while traditional suppliers can only deliver a fraction of that.

Q: How does additive manufacturing make a difference?

Gordie Follin: Additive manufacturing allows us to design parts in ways that weren’t possible before. We can combine features into single parts, introduce more complex design features, while reducing costs, and improving performance and reliability. It also lets us scale from smaller engines to larger ones in a matter of weeks instead of years.

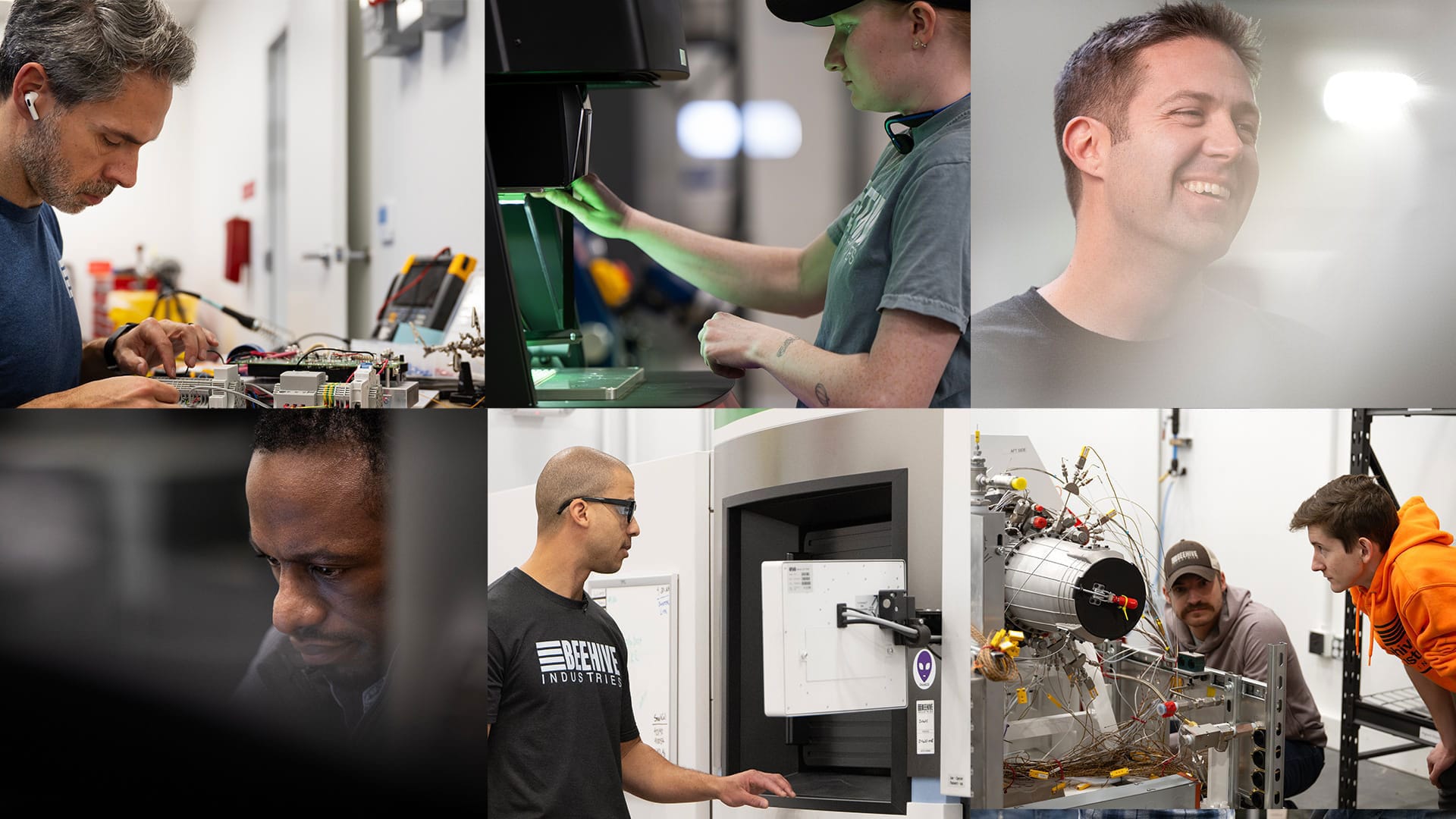

Q: What makes this team equipped to get the job done?

Gordie Follin: Beehive’s secret sauce lies in its people and culture. We have a small but incredibly diverse group of experts who are best-in-class at what they do. When we face a tough problem, we pull everyone together, combine our knowledge, and come up with a solution. This culture of collaboration, risk-taking, and innovation is critical because we’re trying to solve problems no one has before.

Q: What would you say to someone interested in working at Beehive?

Gordie Follin: Beehive is a unique place to work because we’re solving big problems that nobody’s tackled before. I often tell people, "We’re jumping out of the airplane and building the parachute on the way down." That means we embrace ambiguity, take risks, and figure things out as we go. We’re still a startup, and that means every day brings new challenges and opportunities to make a real impact. What I love most about Beehive is the clarity of purpose here—we know what we’re trying to achieve, and everyone is deeply committed to making it happen.

Q: What’s ahead? What does the next five years look like for Beehive?

Gordie Follin: Over the next year, we’re focused on delivering on our first contracts. We have a tight timeline and big milestones to hit within the next 24 months, so proving what we can do is our top priority. Looking five years ahead, I see us producing five engines in full-scale production—two for swarming munitions, two for long-range cruise missiles, and one for collaborative combat aircraft. We’ll also be advancing the next generation of products for more challenging missions, like high mach applications and other disruptive propulsion architectures. The lessons we’re learning now will help us move faster and more efficiently as we go. At Beehive, we’re building something special, and I’m excited about what’s to come.

With a team of top experts and the ability to scale production like never before, Beehive is set to redefine the defense industry. The next five years will bring even greater impact, proving that when you remove the limits of traditional manufacturing, anything is possible.

Interested in working at Beehive? Check out our careers page.