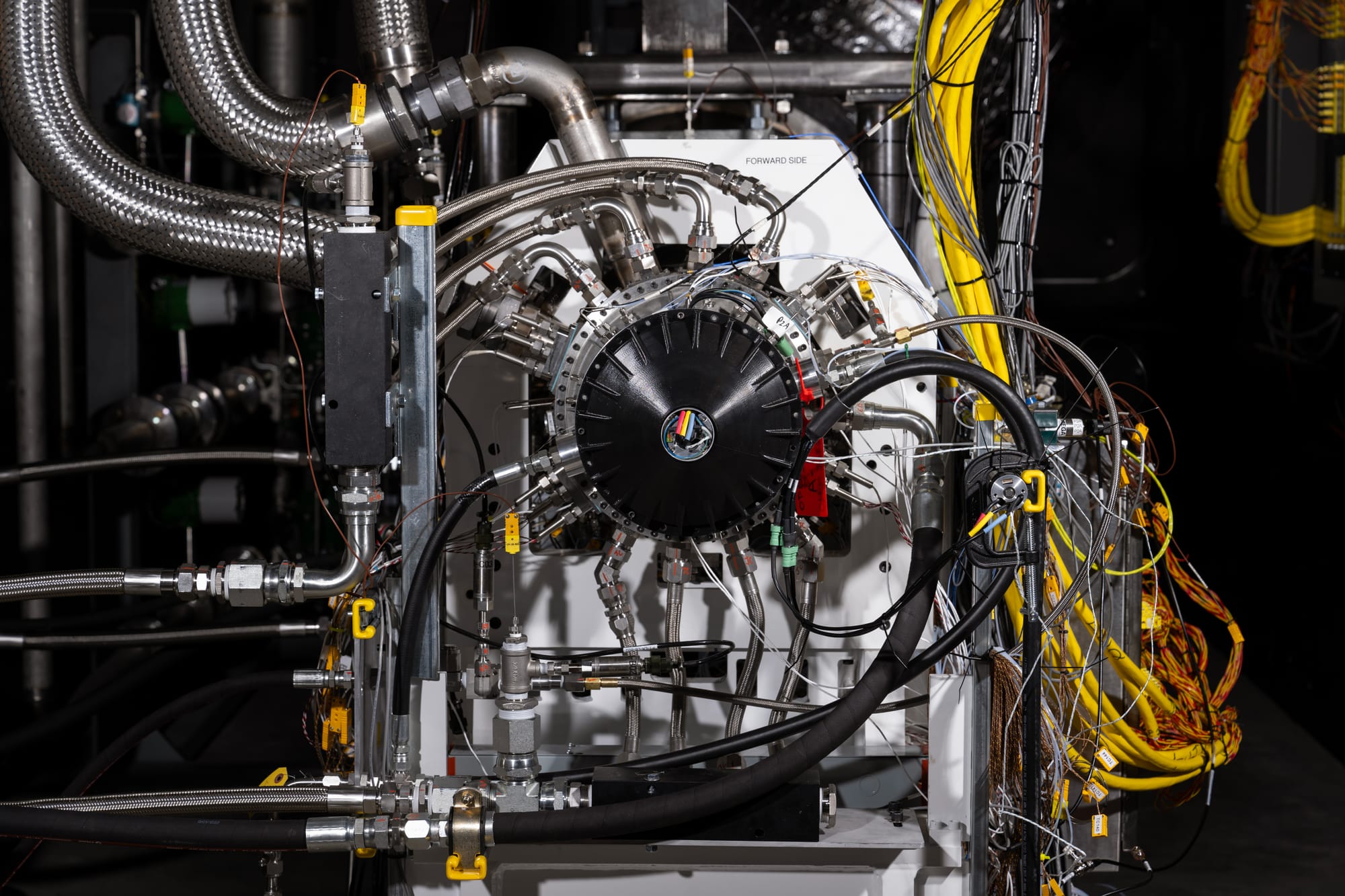

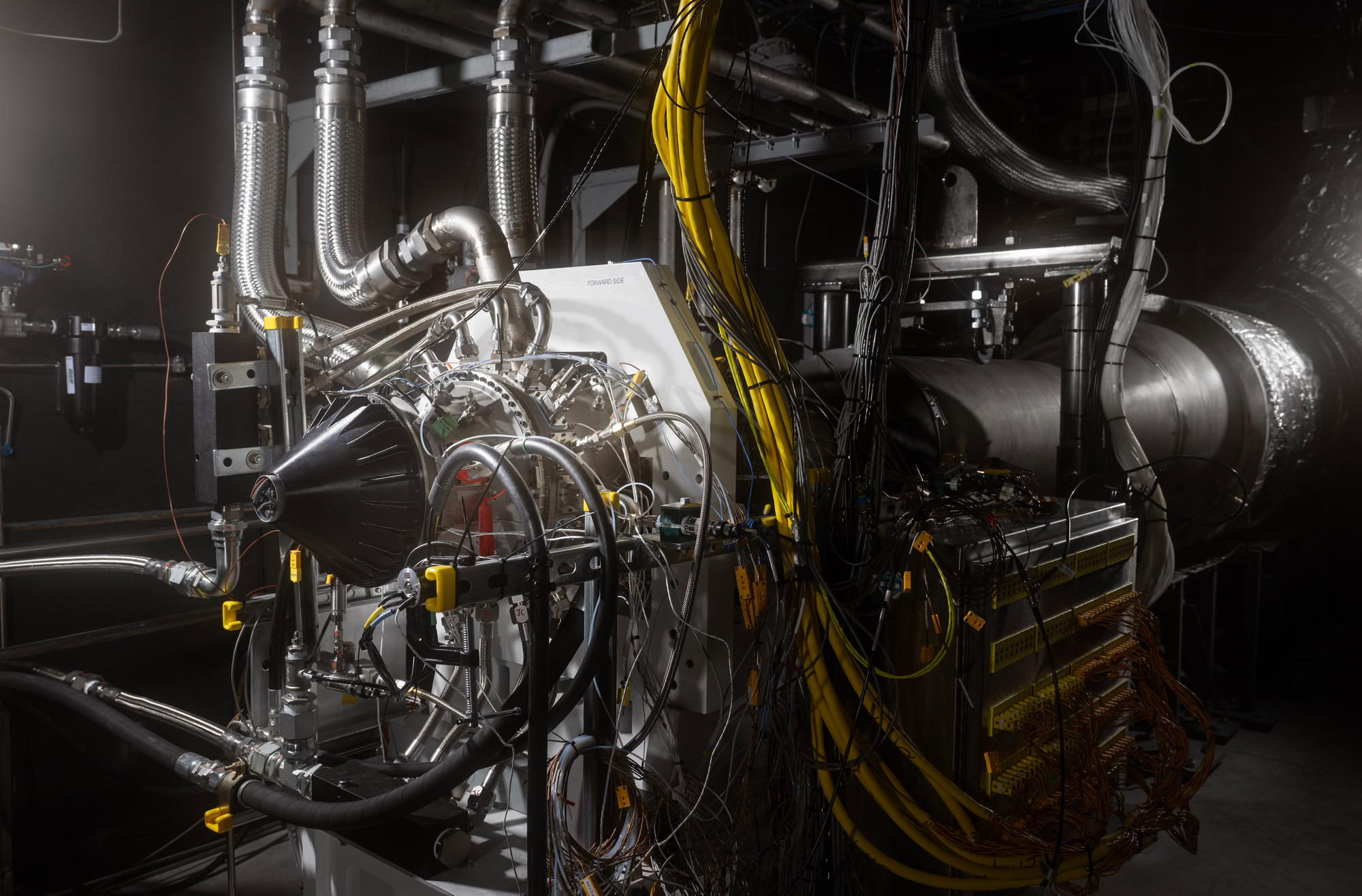

Beehive Industries Completes First Fire Tests for 3D-Printed Jet Engine

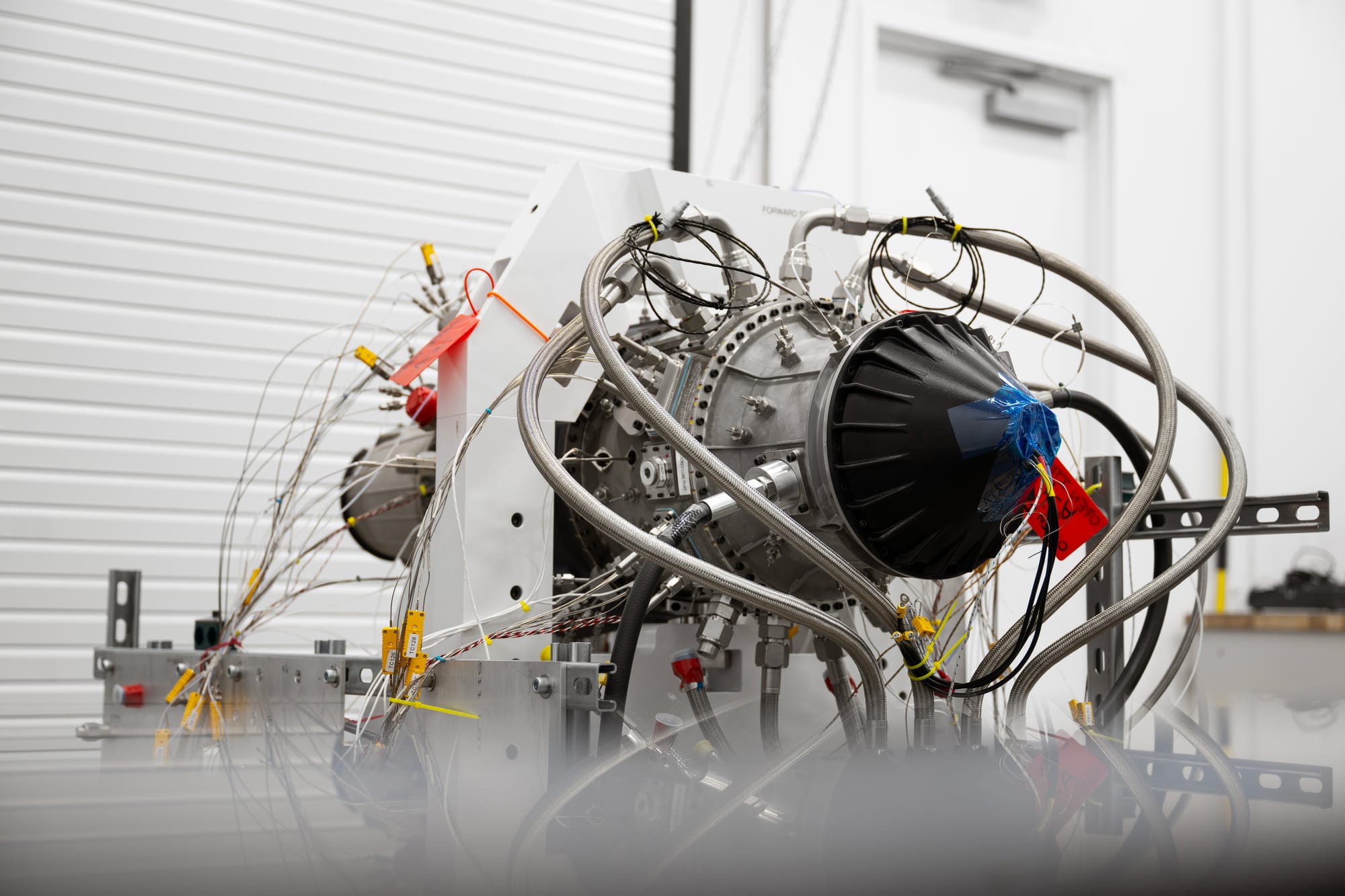

From clean sheet design to fully assembled engine in 13 months, the 500 lbf demonstrator is the first additively-enabled propulsion system made for defense.

Denver, CO (March 25, 2024) Beehive Industries, the additively-enabled jet propulsion company, today announced the successful completion of first fire tests for its 3D-printed engine demonstrator.

This engine is a high-efficiency, attritable engine designed for unmanned aerial defense vehicles such as cruise missiles, collaborative combat aircraft, and reconnaissance and contested resupply drones. As a demonstrator, it represents a future class of engines with thrust capacity ranging from 250 to 1,000 lbf and informs other thrust classes also in development. The design features 90% part consolidation, allowing a price approximately half that of traditionally developed engines.

“This is a huge milestone for Beehive Industries, as well as our country,” said Beehive CEO Mohammad Ehteshami. “This 500 lbf program is demonstrating the untapped potential of additive manufacturing for defense applications. I believe we are only scratching the surface of what’s possible for additive and defense.”

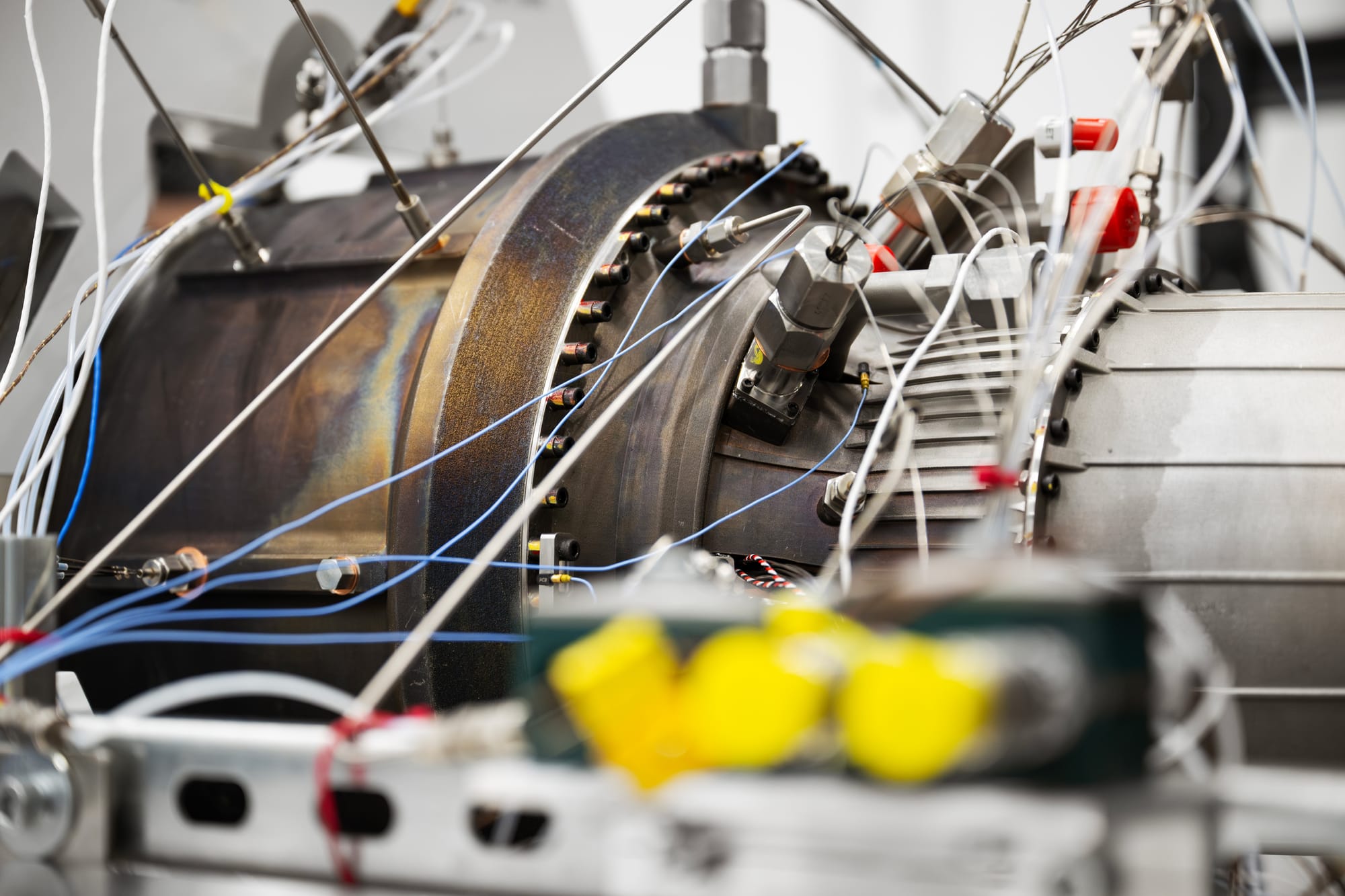

First fire is a significant milestone in the development of any new jet engine, whereby the engine produces thrust for the first time as fuel is ignited within the system. It is the first in a series of tests to validate first engine performance known in the industry as FETT (first engine to test). Typically, it can take several years to reach this stage. At Beehive, it took only 16 months.

“The rapid design and production of the engine was made possible with an incredibly talented team and 3D printing; you simply couldn’t manufacture its design with castings and forgings,” said Beehive VP of Engineering David Kimball. “Beehive consolidated hundreds of traditional engine parts into just 15 primary components. This allows us to bring tailored engines to market rapidly, and in the long run, ship thousands of similar engines faster and more affordably than with traditional manufacturing.”

Utilizing its existing capacity, Beehive is poised to mass-produce 3D-printed engines for American defense applications. Customers can expect to work directly with Beehive to produce propulsion systems with custom performance metrics across thrust, payload, and/or range.

“This is innovation in America, for America,” said Ehteshami. “The 500 lbf demonstrator and Beehive’s family of engines are part of a much bigger initiative to strengthen the American supply chain and modernize our country’s defense capabilities.”